Drinking water data

|

Name of the operator: |

InfraLeuna GmbH |

|

Address: |

Department of Water Systems, Water Supply Division |

|

Water supply area: |

B91 industrial estate (supplied to the Midewa company) |

|

Number of people supplied: |

approx. 12,500 |

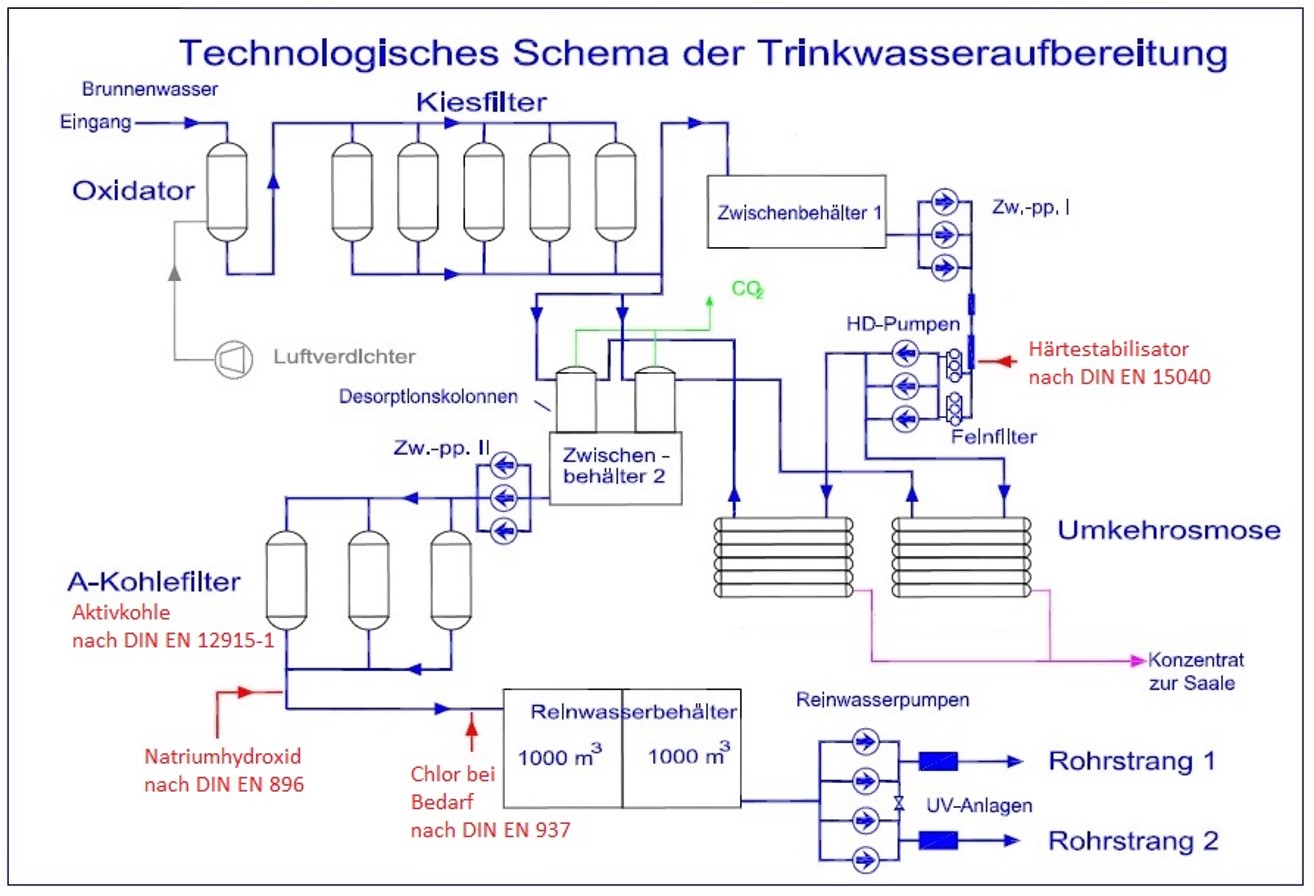

Using 26 groundwater wells, which are distributed around the Saale, groundwater is extracted from a depth of around ten meters and pumped into the drinking water plant via a pipeline system. A multi-stage purification process takes place here. In order to remove any existing turbidity and solids from the groundwater, the first treatment step is mechanical purification using filter gravel.

The high salt content of the groundwater must then be reduced. This is done using the reverse osmosis process. Part of the water is pressed through special membrane modules and thus desalinated - an energy-intensive but necessary process step. Partial desalination makes the water significantly softer. After purification using activated carbon filters and disinfection with ultraviolet light, the water leaves the drinking water plant with a hardness of 7-9°dH. This drinking water treatment process guarantees quality in accordance with the Drinking Water Ordinance.

The following treatment substances are used to turn the well water into drinking water:

- Hardness stabilizer in accordance with DIN EN 15040 to prevent hardness precipitation in the reverse osmosis system

- Hydrochloric acid in accordance with DIN EN 939 to reduce the carbonate hardness in the inlet of the reverse osmosis system

- Sodium hydroxide in accordance with DIN 896 to adjust the pH value equilibrium

- UV disinfection for continuous disinfection of the drinking water

- Chlorine in accordance with DIN EN 937 for the disinfection of drinking water as required in the event of microbiological abnormalities

Annual values 2024 - Daspig drinking water plant

The water constituents listed are an excerpt from the regularly conducted testing program. The concentrations are average values from the year 2024.

The limit values of the applicable Drinking Water Ordinance (TrinkwV) are specified. During treatment at the Daspig waterworks, sodium hydroxide is added to adjust the pH value and chlorine is added for disinfection (if required).

| Parameter | Unit | Mean value | Limit value | Test frequency / number per year |

|

|---|---|---|---|---|---|

| General parameters | Measuring temperature (ph) | °C | 13 | 98 | |

| Hardness | °dH | 7,46 | 98 | ||

| Hardness | mmol/l CaCO3 | 1,33 | 98 | ||

| Hardness range* | Soft (1) | ||||

| Carbonate hardness | °dH | 4,95 | 97 | ||

| Acid capacity | mmol/l | 1,83 | 97 | ||

| Base capacity | mmol/l | 0,017 | 97 | ||

| Calcite dissolving | mg/l | -1,1 | 5 | 97 | |

| Calcium | mg/l | 39,9 | 98 | ||

| Calcium | mmol/l | 0,994 | 98 | ||

| Magnesium | mg/l | 8,2 | 98 | ||

| Magnesium | mmol/l | 0,337 | 98 | ||

| Kalium | mg/l | 3,8 | 98 | ||

| Kalium | mmol/l | 0,097 | 98 | ||

| Natrium | mg/l | 77,8 | 200 | 98 | |

| Total alkaline earth metal | mmol/l | 1,35 (2) | |||

| Phosphorus | mg/l | < 0,05 | 2 | ||

| o-phosphorus | mg/l | < 0,0583 | 98 | ||

| Chloride | mg/l | 95,5 | 250 | 98 | |

| Fluoride | mg/l | < 0,1 | 1,5 | 2 | |

| Nitrate | mg/l | 2,5 | 50 | 98 | |

| Sulphate | mg/l | 86,1 | 250 | 98 | |

| Electrical conductivity | µS/cm | 684 | 2790 | 98 | |

| Ph Value | - | 8,16 | 6,5-9,5 | 98 | |

| True coloration (SAK 436 nm) | 1/m | < 0,05 | 0,5 | 98 | |

| Turbidity | NTU | < 0,09 | 1 | 98 | |

| Oxygen | mg/l O2 | 8,62 | 98 | ||

| Microbiological parameters | Coliform bacteria | n /100ml | 0 | 0 | 24 |

| Escherichia coli | n /100ml | 0 | 0 | 24 | |

| Enterocco | n /100ml | 0 | 0 | 24 | |

| Colony count, 22°C | n/ml | 0 | 20 | 24 | |

| KColony count, 36°C | n /ml | 0 | 100 | 24 | |

| Inorganic trace substance | Aluminium | mg/l | < 0,01 | 0,2 | 2 |

| Ammonium | mg/l | < 0,0193 | 0,5 | 98 | |

| Antimony | mg/l | < 0,0005 | 0,005 | 2 | |

| Arsenic | mg/l | < 0,0005 | 0,01 | 2 | |

| Lead | mg/l | < 0,001 | 0,01 | 2 | |

| Boron | mg/l | 0,27 | 1 | 2 | |

| Bromate | mg/l | < 0,002 | 0,01 | 2 | |

| Cadmium | mg/l | < 0,0005 | 0,003 | 2 | |

| Chlorate | mg/l | < 0,05 | 0,07 | 2 | |

| Chlorite | mg/l | < 0,05 | 0,2 | 2 | |

| Chromium | mg/l | < 0,0005 | 0,025 | 2 | |

| Cyanide | mg/l | < 0,005 | 0,05 | 2 | |

| Iron | mg/l | < 0,005 | 0,2 | 98 | |

| Silicic aid (SiO2) | mg/l | 2,29 | 98 | ||

| Copper | mg/l | < 0,005 | 2 | 2 | |

| Managanese | mg/l | < 0,005 | 0,05 | 98 | |

| Nickel | mg/l | < 0,002 | 0,02 | 2 | |

| Nitrite | mg/l | < 0,016 | 0,1 | 98 | |

| Mercury | mg/l | < 0,00005 | 0,001 | 2 | |

| Selenium | mg/l | < 0,001 | 0,01 | 2 | |

| Silicon | mg/l | 1,23 | 2 | ||

| Uranium | mg/l | < 0,001 | 0,01 | 12 | |

| Organic trace substance | Benzene | mg/l | < 0,0001 | 0,001 | 2 |

| Bisphenol A | mg/l | < 0,00005 | 0,0025 | 2 | |

| TOC | mg/l | 0,48 | 98 | ||

| Benzo(a)pyrene | mg/l | < 0,0000011 | 0,00001 | 2 | |

| PAK (TVO) | mg/l | < 0,00003 | 0,0001 | 2 | |

| 1,2-Dichlorethane | mg/l | < 0,0002 | 0,003 | 96 | |

| Tri- and tetrachloroethene | mg/l | 0,0000225 | 0,01 | 96 | |

| Total trihalomethanes | mg/l | < 0,000086 | 0,01 | 90 | |

| Total PFAS-4 | mg/l | 0,000007 | 0,00002 | 4 | |

| Total PFAS-20 | mg/l | < 0,00002 | 0,0001 | 4 | |

| HAA-5 | mg/l | 0,0023 | 0,06 | 1 | |

| Radioactive substances | Radon-222 | Bq/l | <0,2 | 100 | 4 |

| Guideline dose parameter value | mSv/a | complied with | 0,1 | 4 | |

| Guideline dose test value | Calculation | 0,27 | 1 | 4 |

*The hardness ranges for drinking water have been defined as follows in accordance with the law on the environmental compatibility of detergents and cleaning agents (Washing and Cleaning Agents Act, WRMG, 2007):

- Hardness range soft: less than 1.5 mmol/l (millimoles) calcium carbonate per litre corresponds to 8.4°dH (German hardness level)

- Hardness range medium: 1.5 to 2.5 mmol/l (millimoles) calcium carbonate per litre corresponds to 8.4 to 14°dH (German degree of hardness)

- Hardness range hard: more than 2.5 mmol/l (millimoles) calcium carbonate per litre corresponds to more than 14°dH (degree of German hardness)

Corrosion behaviour

With the existing water quality, there are restrictions on the use of the following materials:

- Cast iron, unalloyed and low-alloy steels (DIN EN 12502-5)

- Hot-dip galvanised ferrous materials (DIN EN 12502-3)

- Unalloyed and low-alloy ferrous materials (DIN 50930 Part 2)

- Hot-dip galvanised ferrous materials (DIN 50930 Part 3)

- Stainless steels (DIN 50930 Part 4, there is a risk of knife-edge corrosion with brazed joints made with silver-containing brazing alloys)

If copper is used as a material, the change in the quality of the drinking water can be considered acceptable with regard to its properties as a safe foodstuff. If galvanised ferrous materials are used, the change in the quality of the drinking water can be considered acceptable with regard to its properties as a safe foodstuff if the limit values for antimony, arsenic, lead, cadmium and bismuth are complied with in the zinc coating.

Recommendations for saving water

- Shower instead of bathing. Shorter showers

- Turn off the water when brushing your teeth and shaving

- Use an economical shower head

- Use a toothbrush mug

- Install flow restrictors (aerators)

- Use water-saving household appliances

- Wash fruit and vegetables in a bowl of water

- Wash dishes in the dishwasher

- Wash your car in a car wash with water recycling

- Water plants in the morning and evening. Preferably with rainwater

Avoidance of stagnant water

Stagnant water is water that stands still in pipework systems for longer than four hours and harbours an increased risk of germ multiplication, particularly legionella and pseudomonads. Long stagnation times can also lead to the mobilisation of substances from the installation materials. To prevent stagnant water from forming, pipes should be flushed regularly and shut off during long periods of absence.

Information on lead pipes in accordance with §17 of the Drinking Water Ordinance

Ask your property owner or manager what material your domestic installation is made of. If lead pipes are still installed, they must be replaced. If he does not fulfil this obligation, the health authority must intervene. The German Drinking Water Ordinance stipulates a limit value of 0.010 milligrams per litre for lead in drinking water. This value can only be guaranteed with a lead-free supply pipe. Existing lead pipes should therefore be replaced as soon as possible. Replacement must take place by 12 January 2026 at the latest.

Risk management

Risk management in accordance with Section 35 Paragraph 3 Sentence 2 Number 7 is in preparation.